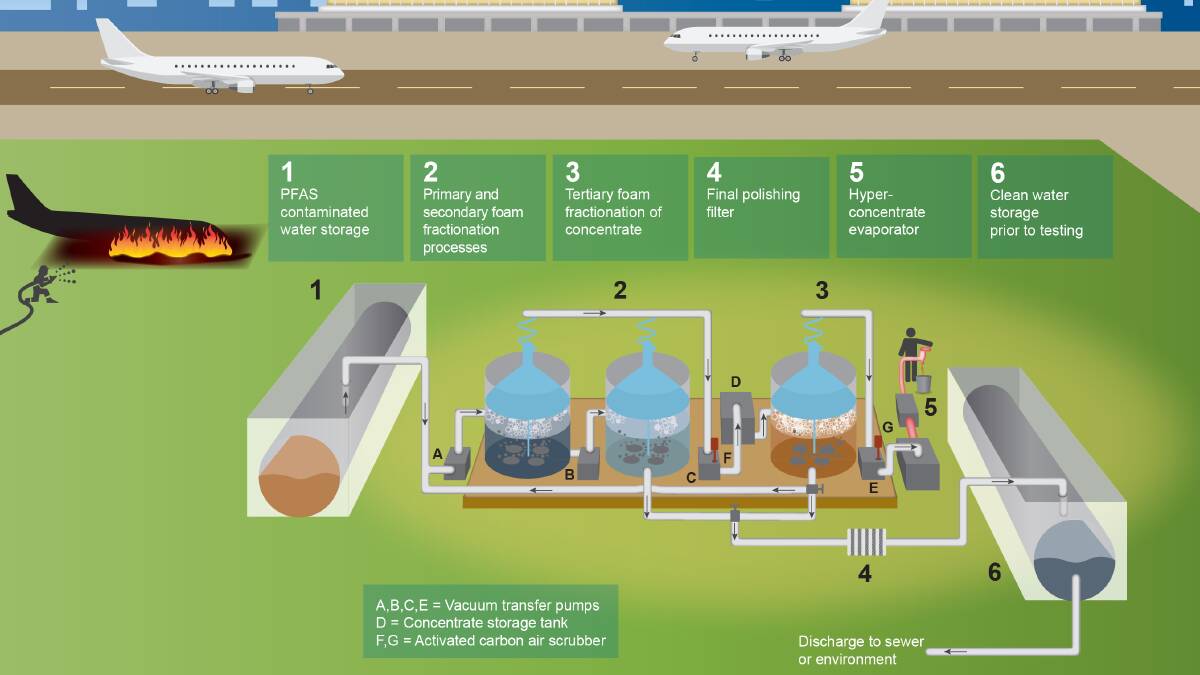

Scientists from a privately owned Australian company, OPEC Systems, claim to have developed a new technology known as Surface Active Foam Fractionation to remove PFAS compounds from contaminated water.

Subscribe now for unlimited access.

or signup to continue reading

Independent NATA testing demonstrates that the technology simply and effectively removes over 99.95 per cent of priority PFAS compounds from source water, meeting recreational use standards within minutes.

Subsequent polishing with other well established technologies enables remediation to drinking water guidelines, the company says.

“SAFF has the potential to effectively treat thousands of sites containing PFAS contaminated waters both in Australia and worldwide, and brings a much needed solution for those organisations currently storing PFAS contaminated waters on site with no effective disposal route,” OPEC environmental division manager, Steve Phillips, said.

The science of removing PFAS from water is developing fast.

The Department of Defence paid to bring technology from the US to treat drinking water in Katherine last year.

The Katherine plant was designed by Emerging Compounds Treatment Technologies that uses a synthetic substance to filter PFAS from water called Ion Exchange Resins.

But the plant only treats a portion of the town’s water.

OPEC Systems says SAFF technology is ideally suited for on-site treatment of PFAS contaminated above ground bulk water stores at places such as airports, industrial locations, refineries and defence sites. It can also be used to treat bore water as it exits the ground, promising relief for rural communities experiencing PFAS contamination in their stock and irrigation waters.

Water processing capacity for SAFF is scalable, with a base model system designed to process 500 litres per hour from a 1.5 x 2.4m forkliftable platform. The modular system design has capacity for limitless expansion, with engineering designs for a 10,000 litre-an-hour system currently being finalised.

“Target PFAS contaminants have a fortunate tendency to foam when aerated. Using a simple ‘Air in – PFAS out’ approach, our SAFF technology successfully exploits this characteristic to remove PFAS compounds from water.”

SAFF technology treats PFAS contaminated water on site within specialised fractionation columns. Air is introduced into the column of PFAS contaminated water through a diffuser, and the resulting bubble column rises to produce a contaminant rich foam on the water surface, which is extracted using a uniquely designed vacuum extraction system.

After the first run through, treated water is reprocessed in a secondary SAFF vessel, before being safely returned to the environment. The extracted PFAS concentrate receives secondary polishing treatments to create a hyper-concentrate which is potentially thousands of times more potent than the original contaminate, before being taken off-site for destruction at a certified waste destruction facility.

OPEC Systems has been working on a solution to PFAS contamination for several years in collaboration with industry, government and specialist tertiary institutions.

“Foam Fractionation has been an exciting success story for our scientists as we work strategically to identify simple and effective ways to remove PFAS contaminants from water sources. During October, we announced our development of a new technology to remove PFAS contaminants from ground water using Downhole Foam Fractionation, and today’s announcement for above ground water sources uses similar scientific principles,” Mr Phillips said.